Power & Protection

As solar energy becomes a cornerstone of sustainable development, the durability of supporting structures is more important than ever. Solar mounting systems must endure wind, rain, extreme temperatures, and UV exposure for decades. That’s where galvanizing plays a vital role. By applying a protective zinc coating to steel components, galvanizing shields them from corrosion and wear.

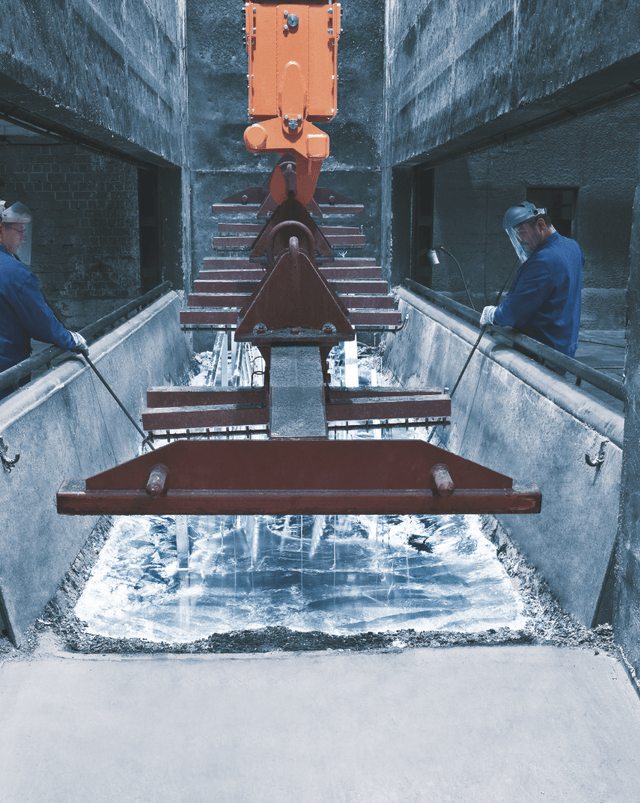

Coatinc United States, Inc. leads the way in solar structures galvanizing, offering reliable, high-performance solutions tailored to the renewable energy sector. With advanced facilities and expert knowledge, Coatinc ensures your solar structures stay strong, stable, and efficient for years to come.